Daughter Board

Our latest thermal test vehicle design consists of a motherboard+daughterboard architecture. The daughterboard contains a 10x14 transistor array to emulate a high-performance GPU. The PCB fits within 6” wafer dimensions for easy processing. The silicon wafer interface provides material match to commercial processors.

Up to 140 hotspots with temp. measurements

> 4 kW power

> 10 W/mm² heat flux

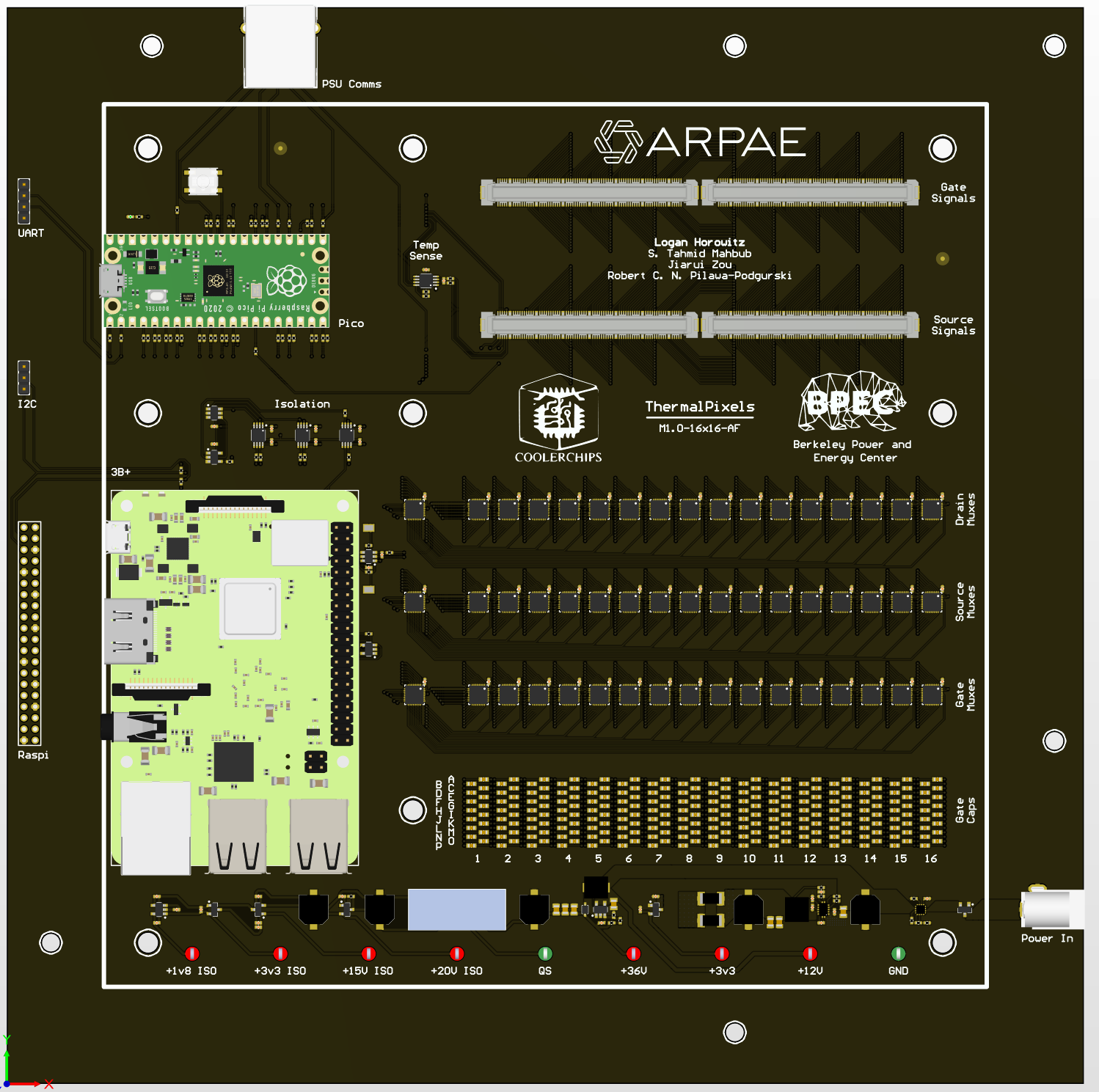

Motherboard

The control electronics and onboard computing are integrated into the motherboard design, capable of controlling daughterboards with up to 256 hotspots with individual temperature measurements. The novel multiplexing scheme enables the use of a singular power supply. The onboard computing is capable of high-speed control and data acquisition, as well as real-time visualization. The flexible compute architecture allows the use of an off-board computer to interface with the low-level electronics if preferred.

Cooling Mount

Our cooler mounting structure is engineered for maximum contact and thermal efficiency. Designed to exert over 120 lbs of mounting force, it ensures a secure and uniform fit for optimal heat transfer. With a pressure exceeding 100 PSI on the array size, our mounting solution enhances cooling performance for high-power workloads, ensuring stability and efficiency under extreme conditions.

Integrated TTV

An integrated thermal test vehicle containing an 11x14 transistor array to emulate a high-performance commercial CPU/GPU, measuring 75mmx75mm. The control electronics and onboard computer are integrated alongside the array onto a single board solution. The novel multiplexing scheme allows the use of a singular power supply.

Up to 154 hotspots with temp. measurements

75mmx75mm array

On-board computer for real-time visualization

> 1 kW power